Assessing the Accuracy of Plastic Pyrolysis Process Clarification

Assessing the Accuracy of Plastic Pyrolysis Process Clarification

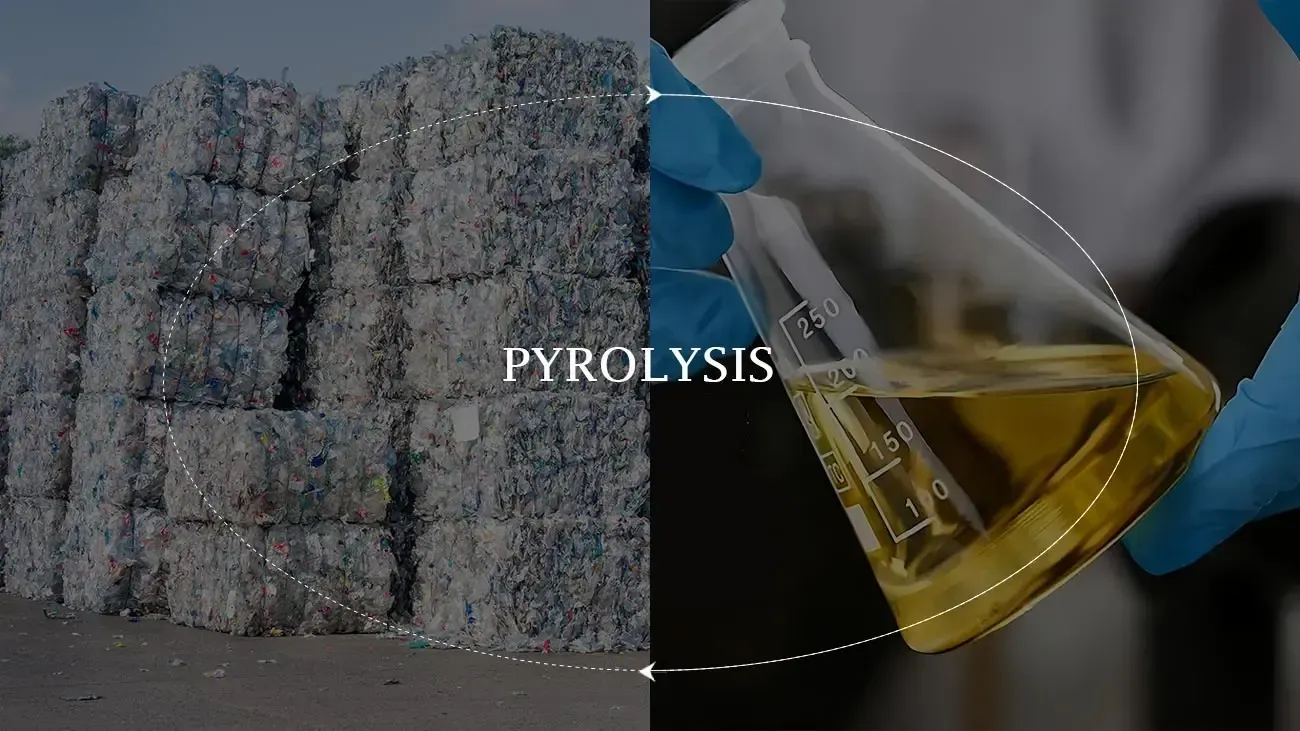

Evaluating the plastic pyrolysis process to determine if it is correctly clarified involves a thorough analysis of several key factors. Pyrolysis is a thermal decomposition process that breaks down plastic waste into valuable byproducts like oil, gas, and char, under controlled conditions of temperature and pressure. Properly assessing this process is crucial to ensure that it meets environmental standards and efficiently converts plastic waste.

First, understanding the feedstock characteristics is essential. The type and quality of plastic waste influence the pyrolysis process. Plastics with different polymer compositions and contaminants can affect the efficiency and output of the process. It is important to evaluate whether the plastic feedstock is properly sorted and cleaned before entering the pyrolysis system.

Next, the reactor design and operating conditions must be scrutinized. The reactor's design affects heat transfer and material residence time, which are critical for efficient pyrolysis. The operating temperature, typically ranging from 300°C to 700°C, must be maintained consistently to ensure complete breakdown of plastic polymers. Variations in temperature can lead to incomplete pyrolysis or the formation of undesirable byproducts. Additionally, the pressure within the reactor can impact the quality of the output products, so it is important to monitor and control these parameters precisely.

The efficiency of the pyrolysis process is also linked to the type of catalyst used, if any. Catalysts can enhance the breakdown of complex polymers and improve the yield and quality of the resulting oil and gas. Evaluating the catalyst's effectiveness and whether it is being used correctly is a key part of assessing the process.

Post-processing and product handling are equally important. The separation and purification of the pyrolysis products, such as oil, gas, and char, should be effectively managed to ensure high-quality outputs. Any residual contaminants or impurities in the products can affect their usability and market value. Therefore, evaluating the processes involved in product handling and purification is necessary to confirm that the system is functioning correctly.

Environmental impact assessment is another crucial aspect. Properly clarified pyrolysis systems should minimize emissions and handle byproducts responsibly. Evaluating the emission control systems and waste management practices is essential to ensure compliance with environmental regulations and standards. This includes checking for the presence of any harmful emissions and verifying that they are being treated or filtered effectively.

Finally, reviewing operational and maintenance practices is important to ensure the longevity and reliability of the pyrolysis system. Regular maintenance, calibration, and monitoring are required to keep the system running efficiently and to address any issues promptly. Evaluating these practices helps confirm that the system is not only clarified but also operates smoothly and effectively over time.

In conclusion, evaluating whether the plastic pyrolysis process is correctly clarified involves a comprehensive review of feedstock quality, reactor design and operating conditions, catalyst use, product handling, environmental impact, and operational practices. A well-clarified process ensures efficient plastic waste conversion, high-quality products, and minimal environmental impact, making it a crucial aspect of modern waste management and recycling strategies.