Benefits Of Sugarcane Bagasse Charcoal Machine

Sugarcane Bagasse Charcoal Machine

Whenever we typically take into consideration sugarcane bagasse, we frequently consider it as worthless waste material. However, it is actually an invaluable supply of biomass material which can be transformed into biochar utilizing the latest sugarcane bagasse charcoal machine

models. If the material is transformed into high carbon charcoal, they have the possible to create large profits for any waste processing facility owner.

Sugarcane Charcoal Making Plant Operations

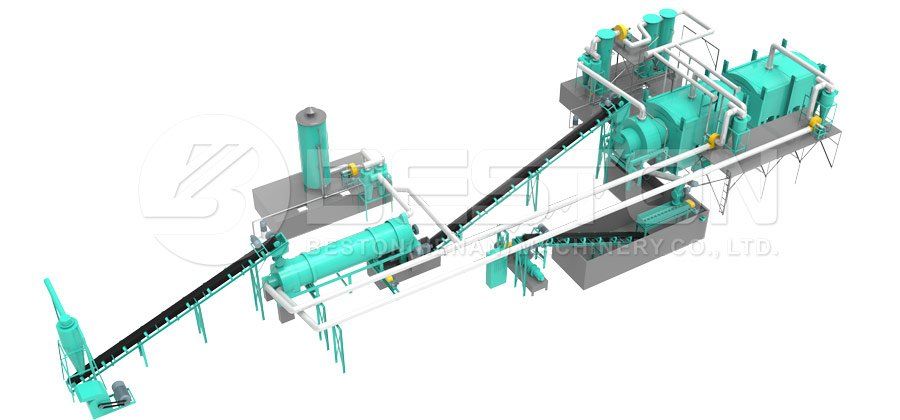

Because of the fact that sugarcane bagasse carries a high moisture content, drying is important just before the carbonization process may start. To guarantee a higher-grade end product, the drying stage can not be skipped. The most effective biomass carbonization plant machine is used to generate biochar using a process of thermal reactions, including sulfur release, smoke volatilization, and carbon enrichment. The sugarcane carbonization furnace is the most crucial component within a biochar making plant.

The pyrolysis reactor dictates the working efficiency and operational lifespan of your machine. Whenever you invest in a charcoal furnace from the top-rated global manufacturer like Beston, you can experience a lengthy machine service life and take advantage of higher rates of return on the initial investment. Click here to know more: https://bestonpyrolysisplant.com/

.

The good news about sugarcane bagasse charcoal making equipment is it is versatile. Meaning, it may process a wide array of biomass materials including peanut shells, palm kernels, straw, coconut shells, manure, sawdust, Bamboo, forest wood, etc. The best biomass carbonization machines have wide application potential, causing them to be a great investment.

In relation to fueling a sugarcane bagasse charcoal machine, most reactors are compatible with a sizable variety of common fuel types. Such fuels generally include gas, coal, flammable gas, biomass, wood, plus more. It's also possible to utilize the biogases produced inside the reactor to reheat the reactor, reducing energy costs. To ensure eco friendly operations, biowaste to charcoal processing plant operators need to use renewable, clean-burning fuel sources to power their sugarcane bagasse carbonization furnaces.

Finished Products

The conclusion products from sugarcane bagasse carbonization include charcoal, tar, wood vinegar, and combustible biogas. The uses of charcoal are very well-known all over the world, therefore it is an extremely marketable product, which is always in high demand. One of many selling points of biochar is it carries a high caloric value and burns cleanly. As previously mentioned, biogas could be used to heat the palm kernel shell charcoal machine

. Tar and wood vinegar are surprisingly useful products. They are utilised to produce fertilizer, mosquito-repellent, and pesticides.

Comparing Biomass Charcoal Making Machines

When it comes to selecting the most appropriate bio charcoal making machine for your establishment, you must take several technical specifications into consideration. A few of these model specifications include hourly feeding capacity, reactor size, total power, working method, cooling method, operating pressure, life span, heating materials, reactor pattern, floor area, automation level, and cost. Obviously, most people are operating under budget restraints, but it's important to never make your cost a deciding factor. Try to find high-quality machines together with the hourly feeding capacity you need to operate a profitable business.