Charcoal Making Equipment: Working Processes And Benefits

Charcoal Making Equipment

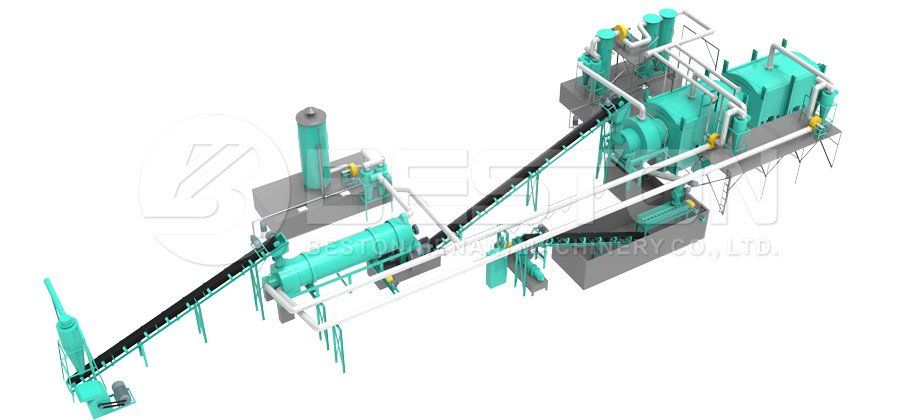

A biomass pyrolysis plant is some industrial charcoal making equipment employed to convert various biomass waste into biochar. It is usually termed as a charcoal making machine

. The raw materials essential for the creation of biochar are any sort of biomass waste for example wood, straw, coconut shells, rice husks, bamboo, palm kernels, etc. It's also easy to use industrial waste through the agricultural sector and farmyard manure.

The biochar produced through the pyrolysis process is a great renewable, low pollution power source which can be used by a variety of industries. The clean burn and calorific price of biochar are what makes it so appealing as being a fuel. However, charcoal powder is also used like a colorant from the pharmaceutical industry plus a soil improver within the fertilizer formulation field. Indeed, the micronutrients found in biochar signify not only does it improve soil drainage properties and root aeration, it can also improve crop yield through providing vital micronutrients to growing plants.

Pyrolysis Plant Use Case

A pyrolysis machine is commonly used to transform biomass waste into charcoal using anaerobic thermal decomposition. This process produces zero pollution and is very energy-efficient. This is because any combustible biogas produced during the reaction is utilized to reheat the principle reactor. The key customers of biomass pyrolysis plant technology are waste processing recycling facilities trying to generate cash in the eco friendly disposable of organic waste. Click here to know more: https://bestonpyrolysisplant.com/

.

Biomass Pyrolysis Processes

To begin with, biomass waste matter are shredded into evenly sized small pieces. Any pieces larger than around 200mm and diameter and thicker than 3 cm may be hard to dry, so waste materials must be shredded into suitable sizes. Once the shredding, waste matter is automatically fed in to the upper area of a piece of equipment for drying. Once dried, the material is transferred in the pyrolysis reactor to endure carbonization. From the oxygen-free, sealed, reactor chamber, the organic waste is carbonized as well as the end products collected via various advanced systems. The end products include biochar, biogas, and bio-oil. All of those products has lots of applications, making them high-value commodities.

Biogas is most commonly used being a fuel. It is fantastic for greenhouse heating systems within the industrial horticulture and agriculture sector. Many fields use biogas to power generators to generate a renewable source of electricity. More information on rice husk charcoal making machine

here.

Charcoal Making Equipment Benefits

There are lots of advantages to buying the most up-to-date biomass pyrolysis machines. Automated continuous machines allow you to produce biochar night and day in huge quantities from cheap waste materials. What's more, automated machines demand a very restricted team of manual worker for operation, so you can make massive savings on labor costs. Automatic technology in biomass pyrolysis reactors means they may have higher efficiency and enhanced safety ratings.

Biomass Charcoal Making Equipment Suppliers

When shopping around to find the best biomass charcoal making machines, make sure the have a look at international manufacturers. Among the best manufacturers of charcoal making equipment happen to be in China plus they have unbeatable prices and free global shipping. Visit the site: https://bestonpyrolysisplant.com/sawdust-charcoal-making-machine/

.