Details About The Rice Husk Charcoal Making Machine

Rice Husk Charcoal Making Machine

Rice husks, just like other kinds of biomass, are mainly thought to be worthless in fact it is a difficult material to recycle. This mainly is related to the husks which can be complex and hard to decompose or break up. This material is also not useful such as compost manures because it takes way too long for these particular materials to biodegrade. The other types of plant materials that share similar properties include corn shells, nutshells, and coconut shells. These materials also take a long time to degrade and also in previous years were mainly dumped. The rice husk charcoal making machine

was developed with the objective of decomposing these harder materials, which includes now rendered them useful again.

The Rice Husk Charcoal Making Machine is utilized for producing high-quality and efficient charcoal the end product made from harder materials including rice husks. These machines assist with converting raw materials into popular demand and valuable products. The process utilizes pyrolysis and carbonization to transform rice husks into something generally known as biochar. Biochar is a kind of charcoal that may be commonly used as a variety of soil amendment. The product is carbon-rich along with a very stable solid that survives from the soil over a number of years. Biochar can also be processed further as a way to produce activated carbon.

The Functionality Featuring Of The Rice Husk Charcoal Making Machine

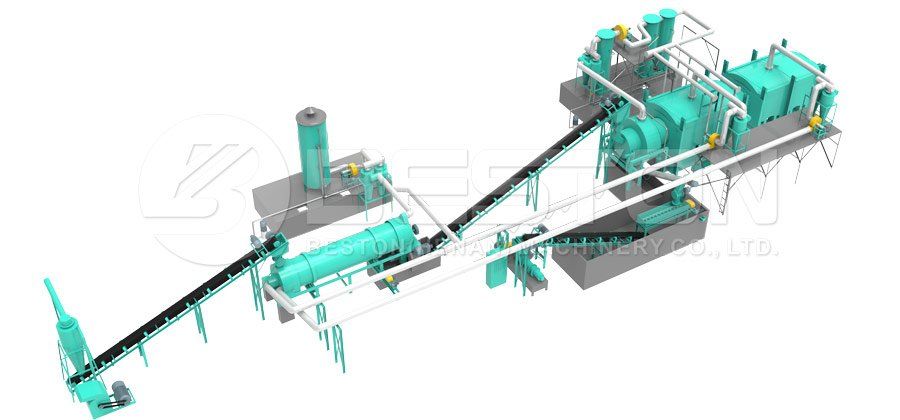

This machine features 4 primary parts including the carbonization machine, flue-gas purification system, a gasification furnace, plus a cooling machine.

In the furnace, the rice husks are subjected to a very high temperature which results in producing flue gas.

From this point the gas enters the gas-purification system where impurities like wood tar are filtered out. Click here to know more: https://bestonpyrolysisplant.com/

.

The purified gas now flows in to a carbonization machine where it undergoes combustion. After the desired temperature is reached, the carbonized materials are then introduced in to the machine via a pipeline transmission. This method ensures that organic combustion has met on top of the 3 required conditions including organic matter, oxygen, and hear. Flue gas that generates from all of these burning materials returns into the machine where it undergoes the whole process of combustion.

Once the gas is purified, this creates consistent thermal energy, which means the device has the capacity to achieve a surgical procedure which is continuous.

The Rice Husk Charcoal Making Machine features an automatic feeder and discharging system, which guarantees a carbonization procedure that is continuous. One side of your charcoal manufacturing plant

feeds the raw materials, along with the other side features a design that discharges the end products. The full process not just protects the nearby environment but saves a significant amount of energy within a smoke-free environment.

The Rice Husk Charcoal Making Machine is an efficient approach to convert useless materials including rice husks along with other hard shells in to a very beneficial by-product. These machines have created possibilities to create wealth from waste that when clogged our landfills and took forever to biodegrade. You will discover a quantity of manufacturers all over the world that sell these appliances and help with the set-up process.