Essential Things You Should Know About Biomass Pyrolysis Plant

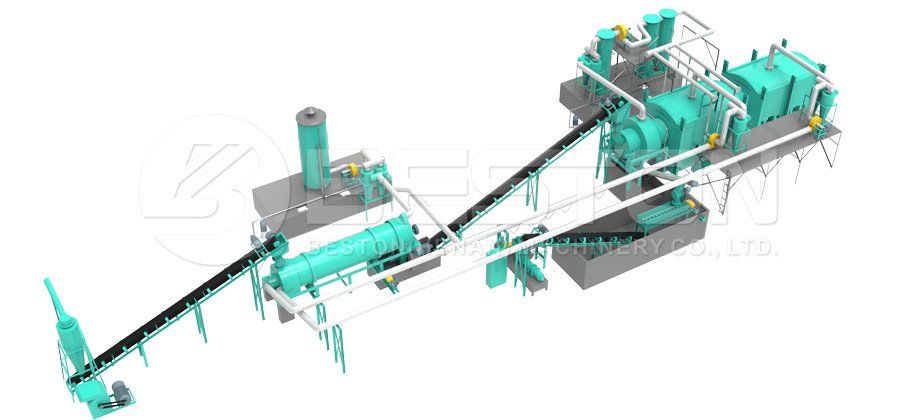

Biomass Pyrolysis Plant

Once you know anything about environmental friendly businesses, you must be aware of the expression pyrolysis. Pyrolysis is actually a technology that can convert waste matter into in-demand products. It's a popular business in several parts around the globe where proper disposal of waste matter like waste biomass, waste tires or waste oil sludge, and also other things is an important problem and requirements a profitable solution.

The biomass pyrolysis plant

supplies a profitable solution to the waste biomass problem. Basically, it is a technique of conversion of solid biomass material into liquid form that may be easily stored and transported. This fuel can be used as manufacturing of chemicals, power and also heat.

So far as the process of biomass pyrolysis is involved, it’s a chemical reaction that reduces biomass in the lack of oxygen. Sometimes, it takes place naturally out in the sector which generates lots of useful fuel for people like us. Inside the biomass pyrolysis process, the final products produced typically include bio-char, bio oil and various gases for example carbon monoxide, fractional co2, hydrogen and methane.

The merchandise derived from the pyrolysis process can be manipulated by changing the thermal environment and temperature in the pyrolysis process. At a temperature of under 450 degrees C together with a slow heating rate, the pyrolysis process will typically produce bio-char. Similarly, pyrolysis process might be manipulated to make mainly gases at the temperature in excess of 800 degrees C with higher heating rate. If your desired item is bio oil, the pyrolysis process has to be performed at intermediate temperature with good heating rate. Click here to know more: https://bestonpyrolysisplant.com/

.

Simply put, pyrolysis process is fairly flexible and might be manipulated differently to generate different types of end products. One of the main reasons biomass pyrolysis has gained popularity is that it may be create at a small-scale and in many cases at remote locations. It's quite useful at improving the energy density of biomass which will help in cutting its transportation and handling costs. As said before in the beginning, pyrolysis process is a wonderful method to convert solid biomass into something much more useful and transportable.

The biomass pyrolysis process is capable of doing working with different kinds of biomass feedstock. A vital thing you must know is that the moisture content in the biomass feedstock is pretty vital for the pyrolysis process. Experts recommend a moisture content of about 10%. In case the moisture content articles are lower, the pyrolysis process may well not produce bio-oil whereas at higher levels, this process will produce much more water.

The particle dimensions of the feedstock also plays a vital role within the efficiency of the pyrolysis process. Therefore, the feedstock must be reduced to a small particle size prior to being fed in the biomass carbonization plant

to derive maximum efficiency from your process.

Pyrolysis process can be of 2 types, namely fast and slow pyrolysis. Inside the fast process, the pyrolysis process takes only a few seconds and yes it yields around 60% bio oil, 20% bio-char and 20% gases. On the flip side, slow process takes a few hours to perform. Within the slow pyrolysis process the amount of bio-char produced is fairly high.

Overall, a biomass pyrolysis plant allows you to perform the biomass pyrolysis process at optimum efficiency. You must dig deeper into the pyrolysis process in line with the above information to determine the proper form of biomass pyrolysis plant you should buy for a successful business setup. Visit the site: https://bestonpyrolysisplant.com/coconut-shell-charcoal-making-machine/

.