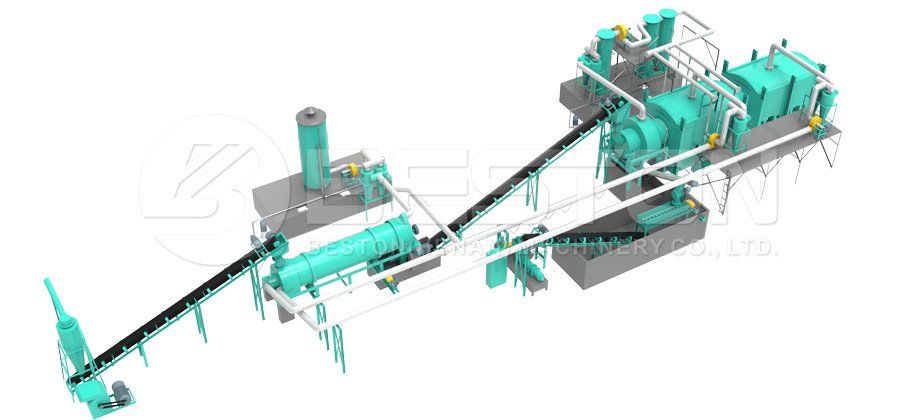

How Biomass Can Be Changed Into Useful Byproducts Having A Pyrolysis Machine

biomass pyrolysis plant

Lately there has been lots of attention paid towards the process called pyrolysis. This is the decomposition of organic waste using heat in the lack of oxygen. When performed correctly, there is no flame with no fire, while there is no oxygen present. This eliminates the smoke and toxic gases that are usually emitted when waste is incinerated. When most waste is decomposed by heat, it stops working into small molecule byproducts like gases, oils, and carbon black. These ingredients can be in love with the open market as well as the problems with vast amounts of waste are eliminated at the same time. What follows is a basic summary of biomass pyrolysis. See the biomass pyrolysis plant

here.

The Fundamental Three Byproducts of Biomass Pyrolysis

When virtually all organic waste elements, whether animal or vegetable, are heated to a high temperature, they breakdown into just their basic components. First there are the gases, methane, hydrogen, propane, butane, and deadly carbon monoxide. The pyrolysis machine will capture the combustible gases and employ these to heat the reactor chamber that makes running the plant very economical.

Another ingredient is oil. There are actually varying numbers of oil, some plastics and tires release huge quantities of oil throughout the heating process. Other biomass products don’t have the maximum amount of oil, however, there is always some. The oil starts out in a super-heated state as a gas and after that is liquefied by way of a condenser unit. You will find sometimes around three grades of oils light, medium, and high, each using its own valuable market. Plus, all of the oils may be refined into dozens of other petroleum products, or burned in industrial burners to create energy or heat. Click here to know more: https://bestonpyrolysisplant.com/

.

The final product, the one that is often overlooked, may be the biochar. This product will take many different forms based on the temperature in the reaction chamber and period in the chamber itself. The more time and better the heat the less combustible the biochar will be. It can be used to produce many products including tires, plastics, and charcoal. When found in agriculture to mix using the soil before planting, it enriches the soil, retains water, and behaves as a carbon sink, storing fractional co2 and delaying climate change.

Most Biomass Needs A Preheater

There are millions of different types of biomass, from coconut shells, to olive seeds, and from corn stalks to rice husks. Every fruit, vegetable, and grain has seeds, husks, stems, stalks, or shells to cope with. There is certainly nearly 1 billion a lot of agricultural biomass created worldwide annually.

The combustible gases that are emitted, captured and saved for usage within the pyrolysis reactor chamber, can be fed for the preheater/grinding machine. Most biomass should hold the moisture content below 25% just to be fed in to the pyrolysis machine. Any biomass that is made from large pieces will have to be ground or crushed to ensure it is heated evenly to find the best efficiency. Why not visit the website: https://bestonpyrolysisplant.com/charcoal-making-machine/

.

There are several variables that can be changed according to what types of byproducts are desired. Most pyrolysis machines might be adjusted to offer more biochar and less oil and gas or less biochar and more oil. It depends around the temperature and amount of time in the chamber. For the best results, check with your manufacturer to see which settings will be required on your machine to obtain the desired results. In any case, you’ll be helping the environment stay cleaner, and possibly store more carbon from the soil to decrease global warming.