Learning More About A Tire Pyrolysis Plant

Tire Pyrolysis Plant

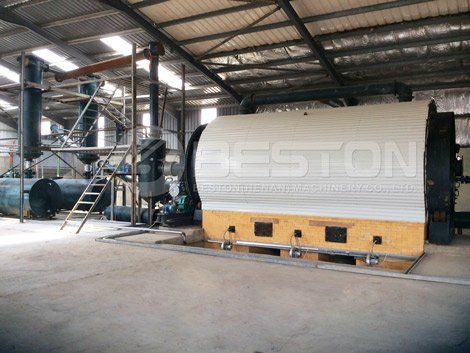

The tire pyrolysis plant combines the batch and continuous type pyrolysis plant. The batch type plant is commonly utilized to feed the raw material using a batch. The appliance can never feed raw material then discharge at the same time. Only after cooling across the plant and discharging the carbon black can the next process begin.

However, the continuous tire pyrolysis plant

is often utilized to feed the raw materials on one particular side. These materials could include plastic and tire, as well as the equipment will discharge the carbon black (final product) continuously in the other side. Both varieties of tire pyrolysis plant are derived from green technology (or pyrolysis) to keep up an environmentally friendly process. Undoubtedly, this is the best tire management solution in terms of tire recycling.

Why Would You Want A Tire Pyrolysis Plant?

There are 2 major reasons for our prime demand for tire pyrolysis machine. Furthermore, with the development of social modernization, the rubber industry has been specifically actively developing. What’s more, the rubber products have wide applications in most works of life, specifically in tire manufacture. On a regular basis, increasingly more scrap particles, including tires, are produced and accumulated to such large amounts. As a result of erode-resistant feature of tires, the main pollution risk was posed to hygiene along with the environment. Click here to know more: https://bestonpyrolysisplant.com/

.

What’s much more important is the fact, when processed using tire pyrolysis equipment, the several types of waste tires might be changed into useful resources. Which resources can be applied in various areas:

1. Tire oil

- Might be sold outward

- Using oil distillation equipment, tire oil can be transformed into gasoline or diesel

- When added into an oil generator, it can generate electricity

- Bring fuel for heating the reactor

2. Carbon black

- May be sold outward

- Could be reprocessed into refractory briquette or coal, and color masterbatch

3. Steel wire

- Could be sold outward

- Using hydraulic press-packing, it may be deeply processed to produce steel bloom

4.Combustible gas

- Could be stored for future use as fuel for heating

- Might be delivered back on the furnace to heat the reactor. Get tyre pyrolysis plant cost

here.

So How Exactly Does the Tire Pyrolysis Plant Work?

The tire refining machine decomposes waste tires inside an very high-temperature process until it creates various kinds of useful resources, which include fuel gas, steel wires, carbon black, fuel oil, etc. Undoubtedly, it’s fascinating that tire recycling equipment will produce renewable resources from pollution and waste.

Raw materials approximately 120mm are suitable with regards to the batch tire pyrolysis plant. This means that relatively large tires must be processed using pretreatment devices. Alternatively, for constant operating in a fully automatic tire pyrolysis machine, it’s prudent to scrap the materials having a dimensions of 30mm to 50mm. However, there are actually certain pretreatment devices suitable to process the full tire.

Undoubtedly, investing in this project or equipment will take in much considerable profit for both the economy and society. Why not obtain one today and save the surroundings! Visit the site: https://bestonpyrolysisplant.com/waste-tyre-recycling-plant/

.