The Basics Of A Continuous Tyre Pyrolysis Plant

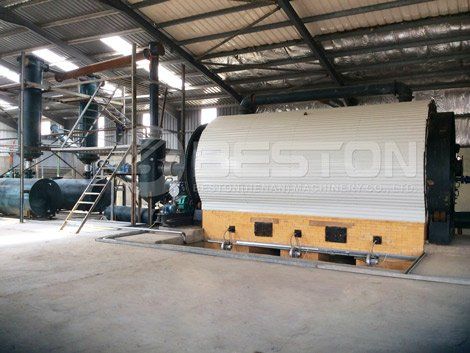

tyre pyrolysis plant

If you are like many individuals, you most likely do not know first thing with regards to a continuous type of waste tyre pyrolysis plant

, much less about pyrolysis itself. However, this really is, rather easy to comprehend.

Pyrolysis is the method whereby used tires and plastic waste are heated and melted oxygen-free, thereby producing by-products that are totally re-usable, like gas fuel for plastic.

A continuous tyre pyrolysis plant can be a plant which has each of the necessary equipment for correct burning on this page. A continuous plant has several parts.

Part one will be the extruding system. The functions with this system include shrinking down tire or plastic into one hot mass. This part is essential since it enhances the amount which can be fed in to the main pyrolysis system. In addition, it speeds up the feeding process, thus shortening the response time.

The other part could be the continuous feeding system. In the extruding system, the material is then moved to the subsequent stage with the feeders. The following stage along the way is absolutely hardly any other as opposed to pyrolysis machine. Even as said before, a pyrolysis machine is where in places you burn plastics and rubber oxygen-free for toxic-free recycling. Click here to know more: https://bestoncompany.com/

.

Following the pyrolysis machine comes the reactor. The reactor is the place the gas coming from the burned rubber and plastic should come out.To be able to seal the gas, a moving-static sealing system is used. This gadget is really important since it prevents the connecting pipes from being bent once the reactor expands.

From the reactor, the gas will be moved to a gas sub package, which stores the gas as an oil tank would store and seal petroleum products continuing.

To be able to increase the company's gas, a continuous-type pyrolysis plant includes a catalyst tower that decolors and desulfurs the gas to make it less toxic to humans. After going through the catalyst tower, the gas might be cooled in a condenser.

The idea behind the continual tyre pyrolysis plant is actually not nuclear physics. You merely process the raw tires to make them better to handle, then you copy in a oxygen-free tank, and you then cool them and store them.

Although it is often a growing industry, the usage of tyre recycling plant

in order to recycle tire and plastic and turn them into fuel gas retains to reach an important mass. Nevertheless the planet is choking in the non-biodegradable waste we produce everyday.

Though if you have thought for your environment, you may perform some research around the different pyrolysis plants being manufactured in the different parts of the world, and spend money on them.

You undoubtedly don't need to concern yourself with creating a bang for your buck. We realize of some businessmen in India who're with such plants to generate fuel to trade with other people. You can do precisely the same in your own country and replicate the success of other businessmen that assist the earth in the operation. Know more about small pyrolysis machine

here.