The Main Advantages Of Biomass Charcoal Making Machine

Biomass Charcoal Making Machine

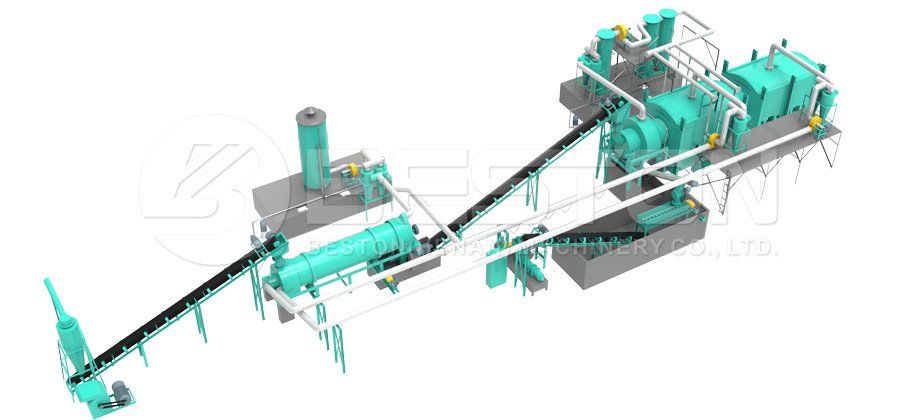

The Biomass Charcoal Making Machine primarily uses carbonization technology. This type of carbonization equipment also goes by other names for example Biochar Production Equipment, Biomass Charcoal Making Machine, Continous Carbonizer, and Biomass Waste Recycling Machine.

Raw materials these particular carbonization machines mainly use include coconut shells, rice husks, bamboo, palm shells, wood chips and much more. The complete process involves high GCV which is short for Gross Caloric Value, superior combustion, low humidity, and the added benefit of not producing CO2 emissions. In addition to these standout advantages, the fuel that is burning is self-supported with the furnace inside of the biochar production equipment for sale

.

The Carbonization Stages Involved With A Biomass Carbonization Machine

Carbonization is definitely the main process necessary to produce biomass charcoal, and that entire working process will include 3 main parts:

1.Biomass Material Drying

To make high-quality charcoal, these biomass carbonizing machines come designed with a drying device. Within this phase in the process, residual moisture is taken away from your materials where there are no chemical changes that occur.

2.The Initial Carbonization Stage

Because the temperature starts to surge in the carbonization furnace, the raw product begins to produce combustible gases in the reactor as well as biomass charcoal. To assure safety inside the operating processes, the charcoal is first shipped to a air conditioning which will drop the temperature from the end product to around 30 degrees. The combustible gases produced can also be processed further which leads to the production of wood vinegar and tar. Click here to know more: https://bestonpyrolysisplant.com/

.

3.The Integrated Carbonization Stage

When the charcoal has been produced from the biomass materials, it may be sold and packaged directly. The combustible gas is really what offers the fuel to the carbonization process. To start with, these combustible gasses are first purified within the spray-dedusting system which works on removing harmful elements and sulfur in order to lower the environmental pollution. The clean gas will then be passed into a condenser system.

With this stage, the equipment will extract the wood vinegar and tar, that are also both useful materials. From this point the gas passes throughout the draft fan where it really is recycled after which accustomed to heat the drying device and the furnace instead of needing to use traditional fuels including natural gas, wood or coal.

Applying this method, the Biomass Charcoal Making Machine achieves self-supporting heat, which not just lowers use of the non-alternative energy sources but in addition protects the surrounding environment. This technologies have been named “one fire with two steps”.

Requirements For Using A Biomass Waste Recycling Machine

•The moisture content from the raw materials has to be under 20%, while the size of the types of materials should be under 50mm. This is why the cracking machine and drying device becomes needed for carbonizing procedures.

•The carbonization usually occurs within fifteen minutes, even though the yield rate of the charcoal is generally 4:1 or 3:1.

•The furnace temperature ranges from 400℃and 600℃, which ensure that the raw materials are completely processed.

The end products manufactured by a biomass pyrolysis plant

include:

•Combustible gas

•Tar

•Biomass charcoal

•Wood vinegar