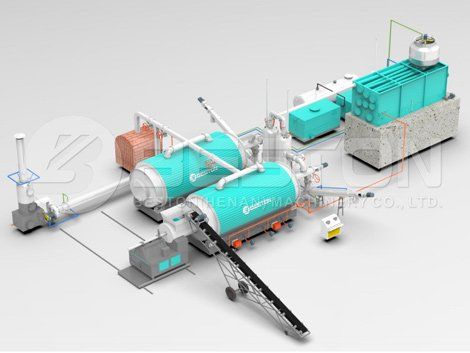

The Most Notable Top Reasons To Think About Using A Continuous Tyre Pyrolysis Plant

Continuous Tyre Pyrolysis Plant

There are far more vehicles being manufactured and sold now than at every other time in history. Although the automotive industry is one of the largest industries that will help to operate a vehicle the global economy, there is certainly one disadvantage in the mass manufacture of vehicles. You can find a huge number of waste tires that happen to be being produced for that reason.

Many of these waste tires are thrown into landfills, and the quantity of tires which can be being thrown from the landfills is increasing each year. The good news is that fully automatic pyrolysis plant

can significantly reduce the quantity of waste tires that end up in these landfills.

Furthermore these waste tires consume lots of real estate property which could serve other uses, these waste products also release dangerous chemicals that may leak into the ground and affect soil and ground water in a area. Fortunately, there are several ways to remove these tires in a method that is not only eco friendly, but also profitable.

The continuous tyre pyrolysis plants can convert waste tires into fuel oil as well as other products by a process known as pyrolysis. To ensure that this procedure to occur, a continuous tyre pyrolysis plant is required.

Which Are The Different Kinds Of Pyrolysis Plants?

There are 2 different types of continuous tyre pyrolysis plants. The first one is really a continuous pyrolysis plant, as well as the second type can be a batch pyrolysis plant. Click here to know more: https://bestonpyrolysisplant.com/

.

Although there are 2 different types of plants, there are many benefits to employing a continuous tyre pyrolysis plant.

Exactly What Are The Benefits Of Using A Continuous Tyre Pyrolysis Plant?

One of the primary disadvantages in utilizing a batch pyrolysis plant is that it most of these plants are certainly not very automated. They might require a great deal of manual labor so that you can work correctly.

Batch pyrolysis plants are not cost effective. After each process, these plants must stopped in order to make sure every one of the end products including carbon black and steel wire are completely from the plant.

Moreover, tires should be fed into waste tyre pyrolysis machine

continuously. Once all the tires have already been processed, the plant has to be stopped so the process can begin over once it has been topped off with more tires.

With a batch pyrolysis plant, this whole process may last provided that 20 hours. This means that it can be unlikely that any fuel oil will be produced.

Another common disadvantage to using a batch pyrolysis processing plant is the fact that this type of plant is not able to process a large amount of stock. Consequently these plants are limited in the level of tires they are able to process.

On the other hand, a continuous pyrolysis plant is able to feed through numerous waste tires. The truth is, there are numerous models on the market that could process over 100 waste tires in just one day. Continuous pyrolysis plants may also be automatic, therefore they require little to no manual assistance.

These are the advantages to employing a continuous tyre pyrolysis plant. They are more efficient than batch pyrolysis plants. Be sure you comparison shop to find the pyrolysis plant that best suits you and budget. Visit the site: https://bestonpyrolysisplant.com/waste-tyre-pyrolysis-plant-cost/

.