Tires Recycling Pyrolysis Equipment Available

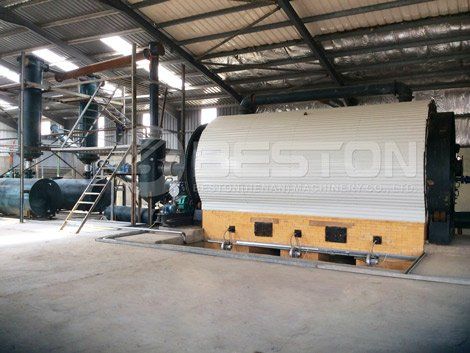

Tires Recycling Pyrolysis Equipment

Vehicles have already been essential in your daily life, and more vehicles mean extra waste tires will probably be produced. Therefore, managing those waste tires has turned into a troublesome problem.

The tyre pyrolysis plant

programs are amazing an environmentally friendly technology to assistance with solving tire as well as other environment pollution that are becoming the adverse issues currently, and it is the important industry.

Nowadays, there emerges a fresh idea recycling those waste tire into beneficial resources we know of as pyrolysis. The fuel oil, one kind of end products obtained from a pyrolysis process, is generally used for producing electricity, heat, steam and much more. If the oil may be distilled employing a specialized pyrolysis oil distillation plant, it can be used for cars.

Besides, the device could also produce steel wire and carbon black, as both versions have broad applications. Nowadays, advanced tires recycling pyrolysis equipment available adopts the pyrolysis technology and possesses the protection features, environmental protection, and energy saving.

The device combines 3 types, like batch, semi-continuous and totally-continuous pyrolysis plant. The main areas of entire pyrolysis system include transmission device, reactor, a cooling tube, catalytic chamber, manifold, light oil tank, heavy oil tank, oil-water separator, oil condenser, safety device, dedusting system, vacuum system, etc.

Every aspect of tires recycling pyrolysis equipment available are produced with advanced technologies and also-quality materials. Therefore, tires recycling pyrolysis equipment on the market is among the most common machines for your environment protection and in high demand on earth.Click here to know more: https://beston.ph/

.

Key top features of the tires recycling pyrolysis equipment

1. This tires recycling pyrolysis equipment available for sale with wide capacity could be operated entirely continuously.

2. The service life span of their reactors increases with hot-air heating technique.

3. Their PLC operation saves manpower.

4. It could be installed because of its modular design easily

Safety forms of the tires recycling pyrolysis equipment available for sale

1. The key pieces of the exhaust gas which can’t be condensed to oil are alkanes which are risky if burned directly. The hydroseal can remove their impurities, sulfur as well as the clean gas may be recycled with a burning room to be used as fuel. Moreover, the hydroseal can stop the gas burning back.

2. It’s fitted with the automatic welding machine that can’t only significantly improve working efficiency, but also provide the welding quality.

3. Professional pressure gauge and thermometer to evaluate pressure and temperature anytime.

4. The latest heating way in which combines some great benefits of direct along with the indirect heating can extend the service duration of the reactor for five to eight years.

5. In the day-to-day operation, the exhaust gas room is closed. In the event that, pressure to succeed is extremely high you can simply open the door of exhaust gas room, as well as the combustion gas may be burned directly that can quickly lower the pressure and temperature in the reactor.

Benefits of pyrolysis machines

1. The main advantage of the tires recycling pyrolysis equipment for sale is that it could work continuously for around the clock.

2. The disposal in the waste tires in an eco-friendly manner is yet another benefit for the pyrolysis plant

.

3. Guaranteed safety and no pollution as they’re fitted with different safety devices.

Products as well as their uses

45% tire oil, 35% carbon black, and 15% steel wire are the 3 end products manufactured by tires recycling pyrolysis equipment on the market that can be utilized inside a wide variety of applications.

For instance, the carbon black can be used constructing bricks or fuel along with clay. The tire oil can be used for burning in different industries or can become diesel or gasoline after further refinement.

The steel wires made using these machines could be recycled or even resold for further processing. This equipment also produces some quantity of the combustible gas during the process which can be used as fuel inside the pyrolysis plant to heat the reactor.

Like this, this machine also lowers its energy needs and save a lot of cash in your case.