Tyre Pyrolysis Plants Helps To Reduce Environmental Concerns Due to Waste Tyres

Tyre Pyrolysis Plant

Our prime usage of vehicles for transportation requires the use of rubber tyres that get exhausted after having a time, and need to be discarded. Earlier they were just discarded in landfills and greatly led to environmental degradation. Technologies have found a remedy of using pyrolysis to process the waste tyres and convert them into useful byproducts.

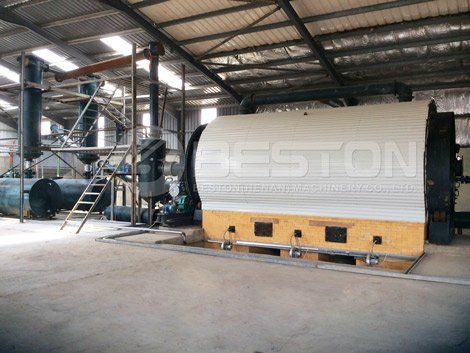

A waste tire pyrolysis plant

consists of a reactor in which the waste tires are gently heated by making use of fuel like coal, wood, LPG, gas, or others. This reactor can have a computerized feeding machine to feed it using the waste tyres. These tyres are frequently shredded prior to being heated, simply because this greatly increases the section of the rubber that needs to be burnt and hastens the process. Shredders will often be part of pyrolysis plants and become installed prior to the reactor and will deposit their materials into the feeding devices.

Once high temperatures are reached in the reactor, this will release oil gas and will also be passed onto condensers that will liquefy the oil and store it in tanks. Lighter gas that is not going to condense might be further treated and fed into the furnace for use as fuel. This will greatly reduce fuel costs for running these pyrolysis plants. Click here to know more: https://bestonpyrolysisplant.com/

.

After the fuel oil is produced the reactor must be allowed to cool down. At these lower temperatures, carbon black is discharged automatically. It is really an important byproduct that sees use within many industries. If we have seen steel within the waste tyres being melted, this has to be removed separately with hooks or magnets and is also a good byproduct that may be sold to recyclers with regard to their use.

Some tyre pyrolysis plants are made to work continuously without stoppage to the recovery of byproducts, making for economical running, as after the reactor is initially charged and fired up, it remains working continuously using the oil gas for fuel, and with arrangements intended to recover the carbon black and steel wires, without interrupting the production process. These plants require a high level of automation when compared with plants that really work with a batch basis. These plants may only need to be stopped for almost any maintenance or repairs and working non-stop for the month or maybe more is not really unknown. They, however, require a lot of care within the material that is fed into them, simply because this should be of the constant quality which fits the particular plant. Batch plants can change their feed quality after every batch. The oil created by tyre pyrolysis plants is effective which is found in furnaces along with other devices that want heating. See the cost of tyre pyrolysis plant

here.

Tyre pyrolysis plants along with their associated technologies have greatly addressed the environmental problem a result of the production of more than 1.5 billion tyres each and every year that ultimately need replacing and grow waste material that must be discarded. These plants could also be used for waste plastic, oil sludge, and other waste that can produce similar byproducts once the necessary treatment. Visit the site: https://bestonpyrolysisplant.com/waste-tyre-recycling-plant/

.