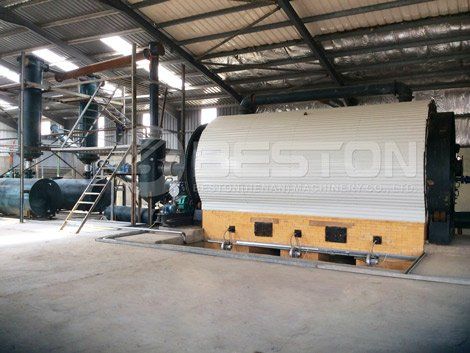

Waste Tire Pyrolysis Plant:The Easiest Method To Recycle Waste Tyres

Waste Tire Pyrolysis Plant

Humankind uses many goods that are just discarded once they have outlived their usefulness. One of the main troubles with these discarded products is simply because they cause environmental degradation.

A number of these discarded products such as tyres and plastics are very unhealthy for the planet given that they contain harsh chemicals that will seep into ground water and pollute it. Additionally, these materials are non-biodegradable which means they keep lying within the landfills but never degrade. The waste tire pyrolysis plant

is used to dispose of waste tire into fuel oil.

Based on estimates by scientists? the most prevalent form of plastic used today will take more than a million years to degrade completely. This is actually the main reason why recycling of tires and plastics has gained much momentum in the last few years.

In addition, many technological advancements manufactured in recent years have made it feasible to recycle waste plastics and tires into various usable products. Perhaps the most common, popular, and successful technology now available for tyre recycling is recognized as pyrolysis. Equipment used to recycle old tires by using this process is known as the waste tire pyrolysis plant. Click here to know more: https://bestonpyrolysisplant.com/waste-tyre-pyrolysis-plant-suppliers/

.

Recycling of tires is actually a growing industry and many people are wanting to get into the business. A waste tire pyrolysis plant makes recycling old tires a piece of cake. One of the best attributes of this technology is that it will not resulted in generation for any waste in the recycling process. The very fact of the matter would be that the recycling process actually produces several useful products including fuel oil, carbon black, steel wire, and hydrocarbon gases.

All of the byproducts are quite popular and fetch decent prices. The technology can also be fully green which means it does not generate any kind of pollution. The complete process can last for about 12 hours but this is dependent upon the telephone number and size of tyres. Many manufacturers build such plants at decent rates.

Whilst the initial investment from the pyrolysis plant can be quite a bit high, it is actually a very lucrative business. It is additionally good to say how the plants are made by professional manufacturers and they are very safe to use. Furthermore, it does not take a lot of time for the manufacturer to deliver a plant and assemble it. Most of the reputable pyrolysis plant manufacturers can deliver a plant in around a months?time.

The process of pyrolysis signifies the decomposition of organic material in the lack of oxygen. The recycling process takes three stages. In the first stage, a feeder supplies the reactor with the components of old tires. This ensures that no oxygen goes into the reactor. Inside the second stage, the tire pieces are then heated slowly for many years up until the tires learn to break up into individual components like fuel oil, gases, carbon black, and steel wire. Final stage involves taking the byproducts off the plant. The tyre pyrolysis plant cost

is affordable.

To summarize, pyrolysis is a proven technology that is certainly cost-effective and pollution free as clearly shown in this article. Invest in a waste tire pyrolysis plant today and view your profits soar as you aid to conserve environmental surroundings.