Why A Rice Husk Charcoal Making Machine Is A Great Choice

Rice Husk Charcoal Making Machine

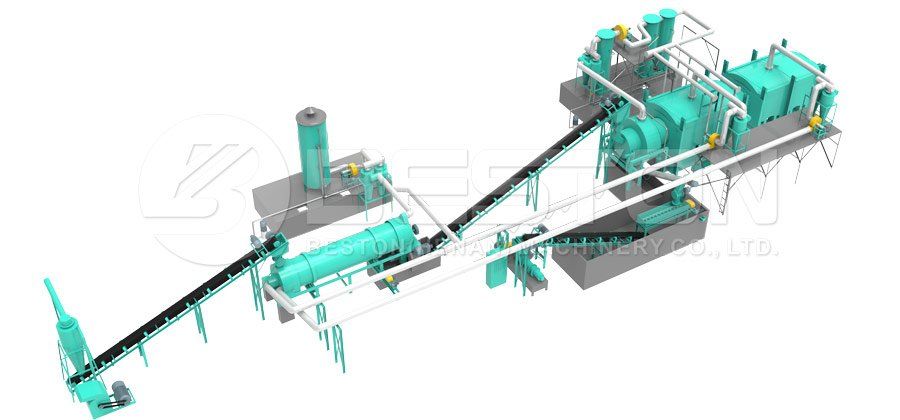

There are many different biochar machines on the market. These biomass machines may use different styles of waste to generate charcoal. If you're going to purchase a unit such as this, and you're unclear what kind of options you ought to be considering, you'll would like to have a close examine a rice husk charcoal making machine

.

It's Easy To Obtain Agricultural Waste

Several of the materials that you can use to produce biochar, like wood, may be costly to maintain. If you're attempting to limit your costs, you'll discover that using agricultural waste like rice husks may be beneficial. It's easy to obtain, and there is a lot of waste around.

It's simple to get hold of these kinds of materials, plus they aren't gonna be a major expense. In reality, according to your circumstances, you may be capable of secure all the materials that you need free of charge. Even though you're purchasing rice husks, you won't have to spend much money. You can find what exactly you need with a very low cost. Click here to know more: https://bestonpyrolysisplant.com/

.

There Are Numerous Rice Husk Machines Available On The Market

Rice husks really are a popular option in relation to making biochar. Due to this, if you do decide to purchase one of these machines, you'll find that you have a lot of different alternatives to select from. You'll have the ability to compare various machines to enable you to find one that's a great buy.

Being limited with your options might be frustrating, especially should you be looking for something that's a tad bit more specific. Seeing as there are all sorts of machines available, you'll be capable of select something which is precisely right for your requirements.

A Piece Of Equipment Like This Could Be Highly Profitable

Without everyone that buys a biomass machine looks to earn a nice gain, it's foolish to ignore the raw earning potential of machines similar to this. There's a lot of requirement for biochar and plenty of buyers that are likely to purchase it in a high price.

The total profits gleaned coming from a charcoal production equipment

similar to this are only gonna be higher if the material which is used to create the charcoal is relatively cheap. Because you normally can obtain rice husks for beside nothing, you'll be able to earn a whole lot with a machine similar to this.

Anybody that is looking to invest in a biomass machine ought to know that a rice husk charcoal making machine is among the best options out there. It's advisable to consider these machines and take into consideration what they need to offer. Consider a range of biochar machines so that you can find an issue that you need to buy.

A rice husk charcoal making machine is a terrific option for many reasons. If you do wind up investing in one of these brilliant machines, you'll have the ability to produce biochar. Whether you sell it or use it for your own needs, you'll be glad that you simply chose a rice husk machine. Visit the site: https://bestonpyrolysisplant.com/sawdust-charcoal-making-machine/

.