Constructing The Best Scrap Tire Pyrolysis Plant Design

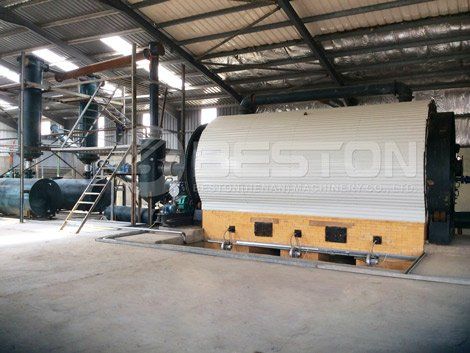

tire pyrolysis plant

A scrap tire pyrolysis plant design is integral to converting the types of materials in tires and plastics into pyrolysis oils, hydrocarbon gas and carbon black for reuse as fuel for steam, heating and electricity. Without having a proper layout and design, the procedure for efficiently transforming the materials could be hindered.

More Details On Scrap Tire Pyrolysis

As many industrial chemists know, pyrolysis can be a chemical process where organic materials are decomposed without the actual existence of oxygen. This happens in cooking procedures like carmelization. Exactly the same process can be and is also accustomed to transform the type of material in tires and plastics so that they can be reformulated into other materials beneficial in the chemical industry. See more about tire to fuel plant

.

With tires, the process of pyrolysis is especially important. Most states in the usa have legislation in position about the proper disposal of tires suited for cars and trucks. As soon as the tires are delivered to a spot to the pyrolysis process, the plant has to be create properly for the end result, which will be to transform the tire material fully into useful fuel like carbon black or pyrolysis oil. The best scrap tire pyrolysis plant design has to be comprised of the appropriate machinery.

What To Incorporate In Scrap Tire Pyrolysis Plants

The style of the plant needs to be organized logically so the process can be carried out efficiently. The correct machinery includes tire shredders and conveyors for the shredded material to become transferred in a pyrolysis reactor.

The tire material must first be placed into an airlock feeding system. This should be the equipment that is certainly positioned at the most logical position in the plant when the scrap tires have already been unloaded. Click here to know more: https://beston.ph/

.

The pyrolysis reactor must be laid next to the airlock system. Next, additional machinery must be arranged depending upon the kind of fuel being culled from your pyrolysis process. For example, for carbon black fuel, there ought to be a cooling and bagging machine that may be arranged nearby so the carbon black could then be loaded on to trucks or into storage.

For pyrolysis oil production, the oil would instead must be transferred and stored to storage tanks engineered for the oil.

Developing The Scrap Tire Pyrolysis Plant

To start the creation of a pyrolysis plant

, have the end result at heart. In the event the desired fuel through the scrap tires is pyrolysis oil, talk to a firm which will help your organization design an appropriate layout using the appropriate machinery and storage for the production of that oil.

Most of the pyrolysis plants created can be done on the turnkey basis. Because of this your organization will get everything necessary to develop and layout the plant from a source. Everything needed is included in the price of its development from the design of specific machinery and its particular manufacturing to its installation. You may even rely on your scrap tire plant developer to assist train your employees in the proper methods to operate all of the machinery.