Benefits Associated With Modern Waste Tire Recycling Equipment

Waste Tire Recycling Equipment

Waste tires are a major issue all over the world. It is estimated that a huge selection of millions of waste tires are dumped in the landfills each year globally. One of the greatest problems with waste tires is that these will not decompose naturally and keep lying within the landfills for years. Waste tires around the landfill sites are also a pollution hazard. The tire recycling plant

is used to recycle waste tires into fuel oil.

The truth is, the situation is really bad in some countries that dumps of waste tires is visible from the International Space Station as big black marks in the world. This is the reason that lots of organizations committed to environmental quality are already seeking a way to eliminate the waste tires in an eco friendly manner.

The waste tires can be recycled in an eco-friendly manner with the aid of pyrolysis liquefaction technique. This technology has been available for a variety of decades but it has become popular before two decades since it allows disposal of waste tires within a sustainable manner. Click here to know more: https://bestoncompany.com/pyrolysis-plant-for-sale/

.

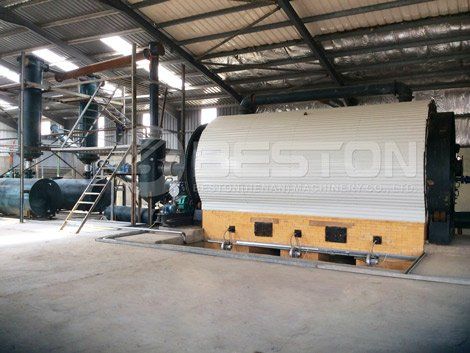

With pyrolysis process, waste tires might be turned into useful industrial oil and carbon black. In terms of the waste tire recycling equipment is concerned, a pyrolysis plant consists of a car feeder system, a reactor where heating takes place, an exhaust system and several safety measures.

A complete-fledged pyrolysis plant having a capacity of about 10 metric tons could be placed in a place close to 400 m? With this technique, waste tires are heated in an oxygen less environment that break down the large molecules of nylon tires into pyrolysis oil, carbon black and hydrocarbon gas.

The majority of the machines on the market today include auto feeder where whole tires can be fed into the reactor without cutting them as a result of pieces. The reactor is a cylindrical tank where the waste tires are heated inside a high-pressure and oxygen less environment. The hydrocarbon gases released during the process passes using a air conditioning to get liquefied. Get tyre to oil plant cost

here.

The gas which remains in liquid state is often delivered back for the reactor system to help in heating the reactor. This may cause the heating process better and saves a great deal of energy. The pyrolysis oil created along the way is collected within a separate tank.

With regards to the level of pyrolysis oil generated from this process is concerned, around 30 to 85% of your raw material is transformed into oil, according to the excellence of the raw material fed into the machine. The plant can work on a continuous basis with one batch of 10 metric a lot of tires being processed in the batch.

The majority of the modern Beston Machinery

waste tire recycling equipment available today works in the completely eco friendly manner. Every one of the waste products generated along the way like waste gas, waste water and waste slag can be used in one way or another.

Not one of the gases or some other material produced along the way can escape the reactor. Overall, the business of turning waste tires into useful materials is gaining popularity as it is not only profitable nevertheless it allows one to get rid of the waste tires in an eco-friendly manner.