Great Things About A Sawdust Charcoal Making Machine

Great Things About A Sawdust Charcoal Making Machine

If you have access to a great deal of sawdust that is certainly just going waste, one of the ways to help you this otherwise waste material would be to convert it into charcoal. Charcoal is actually a highly efficient fuel and also has numerous other uses for example in beauty industry and food industry and others. Converting sawdust into charcoal is easy with the aid of a sawdust charcoal making machine.

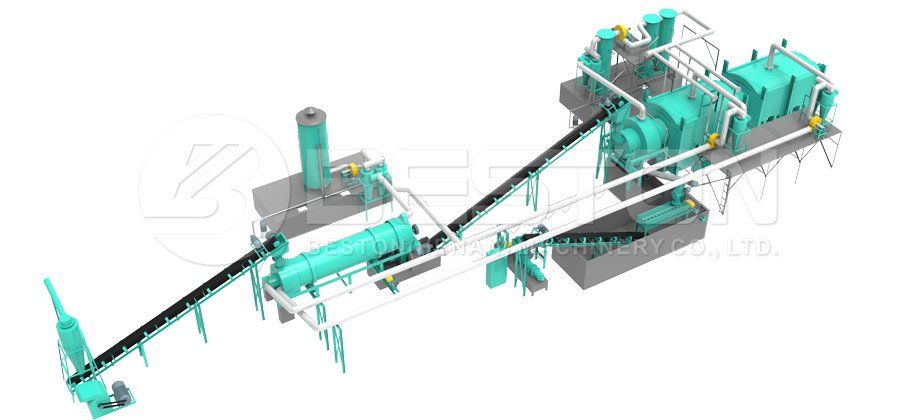

In a continuous sawdust charcoal machine

, recycling sawdust into charcoal takes from twenty to thirty minutes. This is caused by why the reaction happens in a completely oxygen free environment making it faster and in addition, a good deal safer. These furnaces can be bought in a wide array of capacities starting from half a ton hourly to a lot more than 3 ton each hour. In addition to sawdust, this equipment is also suitable for converting bamboo, coconut shells, rice husk as well as other waste materials into charcoal.

The procedure of converting sawdust or other materials into charcoal is pretty simple. Before sawdust is pushed into the furnace, it must be ensured how the moisture content articles are below 20%. When the moisture content articles are high, the process can take a lot longer and the grade of the finished product will not be as great as the item created from raw material with moisture content below 20%. Therefore, a dryer should be used to bring down the moisture content.

In the next step, this dry raw material is pushed from the carbonization furnace. The temperature from the furnace keeps increasing constantly as well as the raw material is converted into combustible gas and sawdust charcoal. Modern machines on the market today take advantage of various tools to capture this combustible gas. Another tool within this machine gets rid of sulfur within the gas. After purification, you will have the option of converting this gas into wood vinegar and tar. Tar is really a waterproof material which is used in a variety of industries because of its high corrosion and wear resistance. Similarly, wood vinegar as traditionally used in food preservatives and it likewise has anti-inflammatory properties which means furthermore, it has medicinal uses.

The sawdust charcoal created in the carbonization furnace is generally too hot to be handled manually. Because of this ,, modern machines come provided with a air conditioning to take across the temperature from the charcoal for even more processing.

With regards to buying a sawdust charcoal making machine is concerned, there are some what exactly you need to consider to get the very best bang for your buck. One of the most important what exactly you need to consider is the efficiency in the machine. It is suggested to decide on a unit that is equipped with a continuous carbonization furnace. Continuous operation is cost efficient and labor efficient. It must also use advanced technology to take care of a lot of the processes automatically.

Another significant parameter you need to examine is definitely the operational capacity from the machine. It is determined by the accessibility of raw material and need for the finished product with your location. Additionally you need to consider the power requirements. Modern machines can typically be powered through a wide variety of fuels such as biomass, natural gas, diesel, wood or charcoal among other options.

Overall, a sawdust charcoal making machine is a good investment when you have ready option of sawdust and also other biomass material for conversion into charcoal. Keep the aforementioned tips under consideration and get a contemporary machine rich in efficiency to obtain the most bang for your buck.Benefits Of A Sawdust Charcoal Making Machine

When you have entry to a large amount of sawdust that may be just going waste, a good way to help you this otherwise waste material is usually to convert it into charcoal. Charcoal is really a highly efficient fuel and also has numerous types of other uses such as in beauty industry and food industry and the like. Converting sawdust into charcoal is not difficult with the aid of a sawdust charcoal making machine.

Within a continuous carbonization furnace, recycling sawdust into charcoal takes from twenty to thirty minutes. This is due to the reason why the reaction occur in a completely oxygen free environment rendering it faster as well as, a good deal safer. These furnaces are available in a variety of capacities which range from half a ton hourly to greater than 3 ton per hour. In addition to sawdust, this equipment is also appropriate for converting bamboo, coconut shells, rice husk and various other waste matter into charcoal.

The whole process of converting sawdust or another materials into charcoal is rather simple. Before sawdust is pushed into the furnace, it needs to be ensured that this moisture content is below 20%. In case the moisture content is high, the method can take a lot longer and the grade of the finished product will never be just like this product made from raw material with moisture content lower than 20%. Therefore, a dryer should be utilized to bring down the moisture content.

Within the next step, this dry raw material is pushed inside the carbonization furnace. The temperature in the furnace keeps increasing constantly and also the raw material is transformed into combustible gas and sawdust charcoal. Modern machines available today take advantage of various tools to capture this combustible gas. Another tool in this machine removes sulfur from the gas. After purification, you will have the choice of converting this gas into wood vinegar and tar. Tar is actually a waterproof material which is used in different industries because of its high corrosion and wear resistance. Similarly, wood vinegar as commonly used in food preservatives and in addition it has anti-inflammatory properties meaning additionally, it has medicinal uses.

The sawdust charcoal produced in the carbonization furnace is typically too hot to become handled manually. This is why, modern machines come provided with a cooling system to take on the temperature of the charcoal for more processing.

So far as purchasing a sawdust charcoal making machine is involved, there are some things you need to think about to acquire the most effective value for your money. One of the more important what exactly you need to check out is definitely the efficiency from the machine. It is suggested to choose a piece of equipment that is equipped with a continuous carbonization furnace. Continuous operation is cost efficient and labor efficient. It must also employ advanced technology to deal with a lot of the processes automatically.

Another necessary parameter you should take a look at is the operational capacity of your machine. It depends on the accessibility to raw material and demand for the finished product within your location. Additionally you need to consider the ability requirements. Modern machines can typically be powered through numerous fuels including biomass, natural gas, diesel, wood or charcoal among additional options.

Overall, a sawdust charcoal making machine is a great investment if you have ready option of sawdust and also other biomass material for conversion into charcoal. Keep those tips under consideration and purchase a modern machine rich in efficiency to get the most value for your money.