Plastic to Oil: Unlocking the Future of Renewable Energy

Plastic to Oil Potencial

The plastic waste crisis is a monumental challenge, one that has prompted the world to seek innovative solutions. Amidst the noise of various approaches, one solution stands out as particularly promising: plastic-to-oil technology. This revolutionary process involves converting discarded plastic waste into usable liquid fuel, offering both an environmentally friendly and energy-efficient alternative to traditional petroleum.

The Science Behind Plastic to Oil

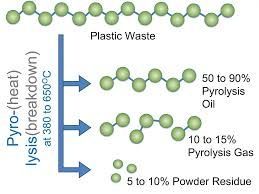

Plastic pyrolysis plants work by subjecting plastics to high temperatures in the absence of oxygen, causing them to break down into smaller hydrocarbons. These hydrocarbons are then condensed into a liquid form, which is a crude oil substitute. The output from these pyrolysis processes can be further refined into diesel, gasoline, or even jet fuel, depending on the specific needs of the market.

This process has the potential to provide an alternative to fossil fuel-based energy, which is responsible for the bulk of carbon emissions and environmental damage. Plastic-to-oil technology could revolutionize the energy industry by providing a renewable source of fuel from what is otherwise considered waste.

A Sustainable Energy Source

One of the key benefits of plastic to oil machine is its role in reducing reliance on non-renewable fossil fuels. As global demand for energy continues to rise, finding alternative sources of fuel is becoming increasingly urgent. By converting plastic waste into usable oil, pyrolysis plants can help reduce the extraction and consumption of natural resources like crude oil, thus contributing to a cleaner, greener energy future.

Moreover, unlike conventional oil extraction, which often causes environmental degradation through drilling and spills, the plastic-to-fuel process involves no new extraction. Instead, it repurposes the enormous amounts of plastic waste that already exist in our landfills and oceans, giving them new life as an energy resource.

Real-World Applications

Several pilot projects and commercial pyrolysis plants have already demonstrated the viability of this technology. For example, companies in Europe and the United States have set up plants that convert plastic waste into diesel, which can then be used in trucks, ships, and industrial machines. Additionally, the technology could be a game-changer for rural or off-grid areas where access to traditional fuel sources is limited.

As demand for sustainable fuel options grows, the global market for plastic-to-oil solutions will likely expand, and this technology will play a central role in the energy landscape of the future.