The Benefits of Plastic Pyrolysis and Distillation

In recent years, the global issue of plastic waste has reached alarming levels, leading to the exploration of alternative methods for managing plastic pollution. Among these methods, plastic pyrolysis and distillation have emerged as promising techniques for breaking down plastics into valuable resources. In this article, we will explore the advantages of these technologies, focusing on their environmental benefits, economic potential, and ability to create a circular economy.

1. Understanding Plastic Pyrolysis and Distillation

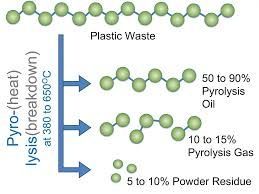

- Plastic Pyrolysis: Pyrolysis is a process that involves heating plastic waste in the absence of oxygen to break it down into simpler compounds. This results in the production of valuable products such as oil, gas, and carbon black, which can be used in various industries.

- Distillation: In the context of plastic recycling, distillation involves separating the different components of pyrolysis oil based on their boiling points. This results in purified products, such as diesel fuel and other chemical compounds, that can be further utilized.

2. Environmental Benefits of Plastic Pyrolysis and Distillation

- Reduction of Landfill Waste: By converting plastic waste into usable products, pyrolysis significantly reduces the volume of plastic waste that ends up in landfills or oceans. This helps alleviate the pressure on waste management systems and reduces pollution.

- Lower Carbon Footprint: Unlike traditional incineration, pyrolysis does not release harmful emissions into the atmosphere. The process is more energy-efficient and contributes to reducing overall greenhouse gas emissions. Distillation further refines the products, ensuring cleaner and more sustainable energy outputs.

- Circular Economy: Both technologies contribute to the creation of a circular economy by turning waste into valuable resources that can be reused, reducing the need for virgin materials and minimizing environmental impact.

3. Economic Advantages

- Energy Production: Plastic pyrolysis equipment converts plastic waste into oil, which can be used as fuel in various industries, providing a potential source of renewable energy. Distillation further enhances the value of this oil by refining it into higher-grade fuels like diesel, which can be used in transportation and manufacturing.

- Job Creation and Innovation: The growth of the plastic pyrolysis and distillation industries can stimulate job creation in research, development, manufacturing, and waste management. The innovation required to optimize these processes also opens the door for new technological advancements.

- Waste-to-Wealth: What was once considered useless waste can now be transformed into valuable products. This waste-to-wealth model not only reduces the costs of waste disposal but also provides an economic incentive for companies to invest in sustainable waste management technologies.

4. The Potential of Plastic Pyrolysis and Distillation in the Future

- Scaling Up: As the demand for sustainable energy and waste management solutions grows, the potential for scaling up plastic pyrolysis and distillation technologies is vast. Governments and private industries are beginning to invest heavily in these technologies, paving the way for widespread adoption.

- Innovation in Recycling Technologies: With ongoing advancements in plastic pyrolysis and distillation, new methods and systems are constantly being developed to increase efficiency, reduce costs, and improve the quality of the end products. This presents exciting opportunities for further innovation in the recycling and energy sectors.

- Sustainability Goals: As nations set more ambitious sustainability goals, including reducing plastic pollution and transitioning to renewable energy sources, plastic pyrolysis and distillation will play a crucial role in helping achieve these targets.

Plastic pyrolysis and distillation offer promising solutions for tackling the growing issue of plastic waste. By transforming waste into valuable resources, these technologies not only reduce the environmental impact of plastic pollution but also provide economic and energy opportunities. As technology continues to advance, we can expect even greater efficiencies and new innovations that will further support sustainability and help build a cleaner, more circular economy.

As the world faces increasing challenges related to plastic pollution, sustainable waste management solutions like pyrolysis and distillation are becoming more critical. By investing in and supporting these technologies, we can contribute to a cleaner, greener future.