Tyre to Fuel Oil: Powering Green Energy Growth

The global waste tyre crisis—with over 1.5 billion tyres discarded annually—poses a severe environmental threat, from landfill overflow to toxic incineration emissions. Meanwhile, the shift to green energy demands sustainable alternatives to fossil fuels. Tyre-to-fuel-oil technology emerges as a brilliant dual solution: it diverts waste tyres from landfills and converts them into a viable, low-carbon fuel source. This innovative process not only tackles a pressing waste problem but also fuels the green energy transition by reducing reliance on non-renewable resources. Let’s explore how tyre-to-fuel-oil is driving green energy development forward.

1. Turns Waste Tyres into a Renewable Fuel Resource

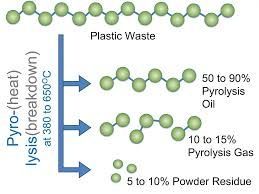

Waste tyres are rich in hydrocarbon compounds—ideal feedstock for fuel production. Through pyrolysis (heating tyres in oxygen-limited conditions), tire to oil plant convert 8-10 kg of waste tyres into 4-5 liters of fuel oil, along with byproducts like carbon black and steel. This fuel oil can replace diesel or heavy oil in industrial boilers, generators, and even marine engines. A medium-scale plant in India processes 50 tons of waste tyres daily, producing 20,000 liters of fuel oil—powering a local manufacturing unit and reducing its fossil fuel use by 35%. By repurposing a waste stream into energy, tyre-to-fuel-oil creates a circular energy model that aligns with green energy principles.

2. Cuts Carbon Emissions vs. Fossil Fuels & Incineration

Green energy’s core goal is decarbonization—and tyre-to-fuel-oil delivers significant emission reductions. Compared to burning coal for industrial energy, tyre-derived fuel oil cuts CO₂ emissions by 25-30%. It also outperforms traditional tyre disposal methods: incinerating tyres releases toxic pollutants like dioxins, while tyre-to-fuel-oil’s closed pyrolysis system captures emissions for treatment. A study in the EU found that a single tyre-to-fuel-oil plant processing 10,000 tons of tyres yearly reduces emissions by 12,000 tons of CO₂ equivalent—equal to taking 2,600 cars off the road. This low-carbon profile makes it a valuable complement to solar and wind energy in hybrid systems.

3. Supports Energy Security & Decentralization

Green energy development relies on reducing dependence on imported fossil fuels—and tyre-to-fuel-oil enhances energy security by leveraging local waste resources. Unlike oil or gas, waste tyres are a domestically available feedstock in nearly every country, reducing energy import bills. Small-scale, mobile tyre-to-fuel-oil units are particularly impactful for rural or remote areas, where grid access is limited. In Kenya, a community-based plant processes local waste tyres into fuel oil to power small generators, providing reliable electricity to 500 households that previously relied on diesel. This decentralization strengthens green energy access and resilience.

4. Drives Industrial Green Transition & Job Creation

Industrial sectors—like manufacturing, construction, and agriculture—are major energy consumers and emitters. Tyre-to-fuel-oil offers a cost-effective way for these sectors to adopt greener energy. A cement plant in Turkey switched to tyre-derived fuel oil for its kilns, reducing its carbon footprint by 28% and saving $200,000 annually on fuel costs. Additionally, the tyre-to-fuel-oil industry creates green jobs: from tyre collection and sorting to plant operation and maintenance. The global tyre-to-fuel-oil sector employs over 100,000 people, with job growth projected at 15% annually as demand for green energy rises.

5. Advances Circular Economy for Holistic Sustainability

Green energy isn’t just about clean power—it’s about holistic sustainability, and tyre-to-fuel-oil is a circular economy star. Every part of the tyre is utilized: fuel oil for energy, carbon black for rubber recycling, and steel for scrap metal. A plant in Germany recycles 100% of its tyre inputs, with carbon black used to make new tyres and steel sold to local foundries. This closed-loop system minimizes waste and maximizes resource efficiency, a key pillar of green energy development. By integrating waste management with energy production, tyre-to-fuel-oil creates a sustainable ecosystem that benefits both the planet and the economy.

Tyre-to-fuel-oil technology proves that waste can be a green energy asset. By diverting waste tyres, cutting emissions, enhancing energy security, and driving circularity, it plays a vital role in the global green energy transition. As governments and businesses scale up sustainable energy solutions, tyre-to-fuel-oil stands out as a practical, scalable option that solves two crises at once. Are you seeing tyre-to-fuel-oil adoption in your region? Share your observations in the comments!