Understanding the Cost of Plastic to Fuel Machines

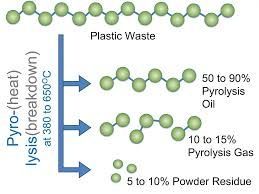

As the global community continues to search for sustainable solutions to manage plastic waste, plastic to fuel machines have gained growing attention. These systems convert discarded plastics into usable fuels through a process known as pyrolysis — heating the material in the absence of oxygen to produce oil, gas, and carbon residue. But one of the most common questions asked by investors, recyclers, and entrepreneurs is: What determines the cost of a plastic to fuel machine?

1. Technology and Design

The overall plastic to fuel machine cost is strongly influenced by the technology used. Systems equipped with advanced condensation units, efficient gas purification, and continuous feeding mechanisms tend to require a larger investment compared to small-scale batch reactors. However, these high-tech designs often provide better energy efficiency and lower operating costs in the long run.

2. Capacity and Output

Machine capacity — how much plastic it can process per day — plays a central role in determining the total investment. A small setup designed for research or pilot use will be significantly different from a full-scale industrial unit that handles tons of plastic daily. Higher capacity systems usually demand more complex engineering, safety controls, and automation.

3. Material and Construction Quality

The build quality of the machine also affects pricing. Units made with high-grade stainless steel, reliable insulation, and corrosion-resistant materials tend to last longer and require less maintenance. The durability of these materials can greatly reduce downtime and enhance overall profitability over time.

4. Automation and Control Systems

Modern pyrolysis plants often include automated control systems, temperature monitoring, and emission management tools. These not only improve safety but also enhance operational efficiency. More automation generally means higher upfront costs, but it can also reduce labor expenses and human error.

5. After-Sales Service and Installation

Installation, training, and after-sales support are often overlooked but important cost factors. Reputable manufacturers provide technical guidance, system optimization, and maintenance services. Choosing a supplier with strong post-installation support can significantly improve performance and longevity.

6. Environmental and Regulatory Considerations

Depending on the region, environmental compliance can also influence the overall cost. Machines equipped with advanced emission control systems may require higher investment but ensure smooth operation under local regulations and sustainability standards.

7. Long-Term Economic Value

While initial investment is important, it’s equally vital to consider long-term benefits — including reduced waste disposal costs, potential energy recovery, and even income from selling the produced fuel. A well-designed plastic to fuel system can transform what was once waste into a valuable resource.

Final Thoughts

The cost of a plastic to fuel machine is shaped by multiple variables — from capacity and materials to automation and environmental design. Instead of focusing only on the purchase price, businesses should evaluate the total value, including efficiency, reliability, and long-term returns. With the right technology and operational strategy, converting plastic waste into fuel is not only a sustainable solution but also a promising business opportunity for the future.