The Future Prospects of Plastic Pyrolysis-to-Fuel Technology

This is a subtitle for your new post

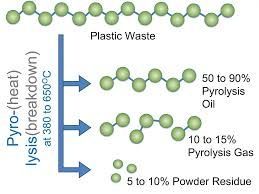

As global concerns over waste management, fossil fuel dependence, and environmental sustainability continue to intensify, plastic pyrolysis technology has emerged as a promising solution. This innovative process converts non-recyclable plastic waste into usable fuels such as pyrolysis oil, diesel-like fuel, and syngas. By bridging the gap between waste reduction and energy recovery, plastic pyrolysis-to-fuel systems offer a compelling pathway toward a circular and low-carbon economy. But what does the future hold for this technology? Let’s explore its potential development and long-term significance.

Rising Global Waste Challenges Drive Adoption

The world produces more than 400 million tonnes of plastic waste each year, and a significant portion of it cannot be recycled through mechanical methods. Traditional disposal methods—landfilling, open burning, and incineration—cause severe environmental problems, including soil contamination, toxic emissions, and greenhouse gas production.

As countries tighten regulations and introduce bans on single-use plastics, the need for alternative waste treatment technologies is growing rapidly. Pyrolysis stands out as an attractive option because it can process mixed, contaminated, and low-value plastics that are typically rejected by recycling facilities. This capability alone positions pyrolysis as a crucial component of global waste management strategies in the coming decades.

Advancements in Technology Improve Efficiency and Safety

One of the key drivers of future growth is the continuous improvement in pyrolysis reactor design, heat transfer efficiency, and emissions control systems. Early pyrolysis plants faced criticism due to inconsistent output quality and high energy consumption. However, new-generation plastic into fuel machine incorporates:

- automated feeding and temperature control,

- catalytic upgrading,

- integrated syngas recovery for self-heating,

- and advanced flue gas treatment.

These innovations significantly enhance fuel quality, reduce operational costs, and minimize environmental impact. As efficiency increases, pyrolysis becomes more commercially attractive and scalable, opening opportunities for both small- and large-scale facilities around the world.

Growing Market Demand for Alternative Fuels

Pyrolysis-derived fuels—especially pyrolysis oil—are gaining acceptance across industrial sectors. They can serve as:

- heating fuels for manufacturing plants,

- feedstocks for refineries,

- precursors for petrochemical production,

- and even potential blending components for transportation fuels after refining.

As major industries work to reduce carbon emissions and diversify their energy sources, the demand for alternative, waste-derived fuels is expected to grow.

Additionally, global energy markets are shifting toward low-carbon solutions. Pyrolysis fuel, when compared with fossil fuels, offers a pathway to reduced net emissions because it transforms existing waste rather than extracting new petroleum. This lifecycle advantage will likely attract more investment and regulatory support in the future.

Supportive Government Policies Strengthen the Outlook

Around the world, governments are introducing incentives, subsidies, and regulations that directly support pyrolysis development. Policies such as extended producer responsibility (EPR), carbon credits, waste-to-energy incentives, and landfill reduction targets make pyrolysis financially attractive.

For example:

- The European Union promotes chemical recycling within its Circular Economy Action Plan.

- Several Southeast Asian countries, facing rising waste volumes, are encouraging private investment in pyrolysis plants.

- In North America and India, legislation is increasingly recognizing pyrolysis as a form of advanced recycling rather than traditional waste disposal.

Such policy support not only legitimizes the technology but also boosts long-term growth and industry stability.

Integration With Chemical Recycling and Circular Economy Models

One of the most exciting future prospects lies in integrating plastic pyrolysis with broader chemical recycling systems. Instead of viewing pyrolysis oil merely as a fuel, many companies are exploring its use as a raw material for producing new plastics and chemicals. When upgraded through hydro-treatment or catalytic refining, pyrolysis oil can become a valuable feedstock for high-quality polymers.

This creates a true closed-loop recycling model—where plastic waste becomes new plastic products—dramatically reducing dependence on virgin fossil resources. As major brands commit to using recycled content in their packaging, the demand for chemically recycled feedstocks is expected to surge.