Advantages of Plastic-to-Oil Machines Compared to Mechanical Recycling

Plastic waste has become one of the most pressing environmental challenges of our time. While mechanical recycling (such as shredding, washing, and remolding plastic) is widely practiced, it faces limitations in handling contaminated or mixed plastics. In recent years, plastic-to-oil machines—which use pyrolysis to convert plastics into fuel oil—have emerged as a promising alternative. Compared to traditional mechanical recycling, this technology offers several distinct advantages.

1. Broader Range of Feedstock

Mechanical recycling requires plastics to be sorted, cleaned, and often limited to certain types such as PET or HDPE. Contaminated, mixed, or multilayer plastics are difficult to process. In contrast, plastic into oil machine can handle a wide variety of plastic waste, including materials that are otherwise non-recyclable, thereby diverting more plastics from landfills and incineration.

2. Producing High-Value Fuel

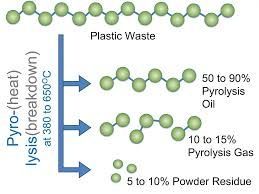

Instead of downcycling plastics into lower-grade products, pyrolysis produces fuel oil, syngas, and carbon black—valuable outputs that can be used in industry or as energy sources. This not only addresses the plastic waste problem but also helps reduce reliance on fossil fuels.

3. Less Dependence on Sorting and Cleaning

Mechanical recycling often requires extensive pre-treatment, including sorting by polymer type and cleaning to remove labels, food residues, and contaminants. Plastic-to-oil conversion is more tolerant of impurities, significantly reducing pre-processing costs and labor requirements.

4. Tackling the “Recycling Gap”

Globally, only a fraction of plastic waste is mechanically recycled because many plastics degrade in quality after each cycle. With pyrolysis, the chemical bonds of plastics are broken down and converted into oil, bypassing the problem of material degradation and extending the lifecycle of plastic waste.

5. Supporting Circular Economy and Energy Recovery

While mechanical recycling focuses on material reuse, plastic-to-oil machines integrate both waste management and energy recovery. The syngas produced during pyrolysis can even be reused as process fuel, improving energy efficiency. This dual benefit strengthens the role of pyrolysis in a circular economy framework.

Conclusion

Both mechanical recycling and plastic-to-oil technology have roles to play in solving the plastic waste crisis. However, plastic-to-oil machines offer clear advantages in handling non-recyclable plastics, reducing pre-treatment requirements, and producing valuable fuels. As the demand for innovative waste-to-energy solutions grows, pyrolysis-based technologies stand out as a complementary and scalable approach to traditional recycling.