Efficiency Advantages of Continuous Tyre Pyrolysis

Waste tyres are one of the most challenging solid wastes to manage worldwide. Traditional disposal methods such as landfilling and incineration not only waste valuable resources but also create significant environmental concerns. Tyre pyrolysis, the thermal decomposition of tyres in the absence of oxygen, has emerged as a sustainable recycling technology. While both batch pyrolysis and continuous pyrolysis are used in the industry, continuous pyrolysis offers clear efficiency advantages that make it a preferred choice for large-scale operations.

1. Higher Processing Capacity

Continuous tyre pyrolysis plant are designed to feed raw materials and discharge end products without interruption. This eliminates downtime between batches, allowing for 24/7 operation. As a result, the throughput is significantly higher compared to batch systems, making it more suitable for commercial-scale recycling plants.

2. Improved Energy Efficiency

Batch pyrolysis requires repeated heating and cooling, which leads to higher energy consumption per ton of tyres processed. Continuous systems, on the other hand, maintain stable operating temperatures throughout the process. This consistent heat utilization reduces fuel costs and improves overall energy efficiency.

3. Consistent Product Quality

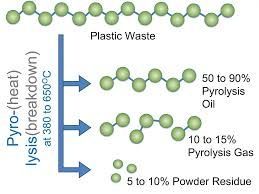

Because continuous pyrolysis maintains steady temperature and pressure conditions, the quality of outputs such as pyrolysis oil, carbon black, and syngas is more uniform. This stability not only improves downstream processing but also enhances the market value of recovered products.

4. Lower Labor and Maintenance Costs

Batch plants require more manual intervention for loading and unloading tyres, as well as cleaning the reactor after each cycle. Continuous systems automate most of these processes, reducing labor requirements and minimizing wear and tear from frequent shutdowns. Over time, this lowers both operational and maintenance costs.

5. Reduced Downtime and Higher ROI

Since continuous pyrolysis plants run non-stop, there is less downtime compared to batch systems. Higher productivity combined with lower operating expenses translates into a faster return on investment (ROI), making continuous pyrolysis a more economically viable solution.

Conclusion

Continuous tyre pyrolysis technology stands out in terms of processing efficiency, energy savings, product consistency, and operational cost-effectiveness. For businesses and governments looking to address the growing challenge of waste tyres, adopting continuous pyrolysis is a forward-looking solution that combines environmental responsibility with economic benefits.