Plastic Pyrolysis and the Energy Transition: Bridging Fossil and Renewable Worlds

Every year, the world produces over 400 million tons of plastic, and less than 10% of it is recycled. The rest ends up in landfills, oceans, or is incinerated, releasing toxic pollutants and worsening the climate crisis. At the same time, the global push for energy transition—shifting from fossil fuels to renewables like solar and wind—faces a key challenge: intermittency. Solar panels don’t work at night, and wind turbines depend on weather, creating gaps in energy supply. Enter plastic pyrolysis: a technology that not only tackles plastic waste but also acts as a critical bridge between fossil fuels and renewables, supporting a smoother, more reliable energy transition.

How Plastic Pyrolysis Works: Turning Waste into Fuel

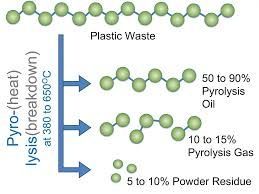

Plastic pyrolysis is a thermal process that breaks down non-recyclable plastic waste (like single-use bags, packaging, and foam) in an oxygen-free environment. When heated to 400–600°C, long polymer chains in plastic split into smaller molecules, producing three main products: pyrolysis oil (also called “plastic crude”), syngas, and char.

The star product, pyrolysis oil, has a heating value of 40–45 MJ/kg—similar to diesel or gasoline. It can be refined into transportation fuels (like biodiesel or jet fuel) or used directly in industrial boilers and generators. Syngas, a mixture of hydrogen and carbon monoxide, can power gas turbines or be converted into hydrogen for fuel cells. Even the char byproduct has value: it can be used as a soil amendment or in carbon capture technologies. Unlike incineration, which releases harmful dioxins, modern pyrolysis plants use closed-loop systems and filters to trap emissions, making the process far cleaner.

Bridging Fossil Fuels and Renewables: A Flexible Energy Solution

One of the biggest hurdles in energy transition is balancing supply and demand. Renewables are clean but inconsistent; fossil fuels are reliable but carbon-intensive. Plastic pyrolysis machine fills this gap by providing a flexible, low-carbon fuel source that integrates with both systems.

For fossil fuel-dependent industries—like shipping, aviation, and heavy manufacturing—pyrolysis oil offers a drop-in replacement for diesel or marine fuel. This means companies don’t need to overhaul their existing engines or infrastructure to reduce emissions. For example, Maersk, the world’s largest shipping company, has tested pyrolysis oil in its vessels, cutting CO₂ emissions by 30% compared to traditional fuel.

For renewable energy grids, pyrolysis acts as a backup power source. When solar or wind output dips (e.g., during cloudy days or calm weather), generators running on pyrolysis oil can quickly ramp up to meet demand. This solves the “storage problem” that plagues renewables, without relying on fossil fuels. In Germany, a pilot project combines a wind farm with a pyrolysis plant, using plastic waste to generate electricity when wind speeds are low.

Environmental and Economic Wins: Making Transition Affordable

Energy transition is often criticized for being costly, but plastic pyrolysis delivers both environmental and economic benefits, making sustainability accessible.

Environmentally, it diverts plastic waste from landfills and oceans. A single ton of plastic processed via pyrolysis prevents 1.5 tons of CO₂ emissions (compared to incineration) and saves 7 barrels of crude oil (since pyrolysis oil replaces fossil fuels). It also reduces microplastic pollution: when plastic breaks down in landfills, it releases microplastics into groundwater, but pyrolysis destroys these particles entirely.

Economically, it creates a new revenue stream from waste. Plastic waste, once a liability for cities, becomes a feedstock worth

50–

100 per ton. For businesses, pyrolysis plants have a relatively quick return on investment (ROI): small-scale facilities (processing 10–20 tons of plastic daily) can recoup costs in 2–3 years. Governments are also backing the technology: the EU’s Renewable Energy Directive classifies pyrolysis oil as a renewable fuel, while countries like Canada and Japan offer tax incentives for plastic-to-energy projects.

The Road Ahead: Scaling Up for a Sustainable Future

While plastic pyrolysis shows great promise, scaling it up requires collaboration between governments, industries, and communities. Key steps include improving the efficiency of pyrolysis oil refining (to meet stricter fuel standards), expanding collection systems for non-recyclable plastic, and investing in research to process more complex plastics (like multi-layered packaging).

Major companies are already leading the way. Shell has partnered with plastic waste management firms to build a large-scale pyrolysis plant in the Netherlands, aiming to produce 80,000 tons of renewable fuel annually by 2026. Meanwhile, startups like Pyrum Innovations are developing modular pyrolysis units that can be deployed in rural areas, turning local plastic waste into energy.

In the journey toward a net-zero future, plastic pyrolysis isn’t just a waste management tool—it’s a strategic enabler of energy transition. By turning plastic trash into a reliable fuel source, it bridges the gap between fossil fuels and renewables, making the shift to sustainability faster, cheaper, and more inclusive. As we face the dual crises of plastic pollution and climate change, this technology proves that solutions can come from the most unexpected places—even our garbage.