Producing EBC-Certified Biochar with a Biochar Making Machine

As sustainability and carbon management gain global attention, biochar has become a hot topic in agriculture, energy, and environmental industries. Not only does biochar improve soil health and increase agricultural productivity, but it also plays a critical role in carbon sequestration, helping to combat climate change. However, not all biochar is created equal. To ensure quality and safety, organizations like the European Biochar Certificate (EBC) have established strict standards for biochar production.

So, how can a biochar making machine produce biochar that meets EBC standards? Let’s explore.

1. What is EBC-Certified Biochar?

The European Biochar Certificate (EBC) is one of the most recognized quality frameworks for biochar worldwide. It ensures that biochar meets strict criteria related to:

- Feedstock (only sustainable biomass is allowed, no hazardous or contaminated materials)

- Production process (controlled pyrolysis with minimized emissions)

- Biochar quality (low heavy metal content, safe for soil application, and stable carbon structure)

- Environmental responsibility (traceable supply chains and sustainable energy use)

Only biochar that passes rigorous testing in accredited labs can carry the EBC label. This certification is especially important for farmers, businesses, and industries that want to use biochar safely and responsibly.

2. How a Biochar Making Machine Ensures EBC Standards

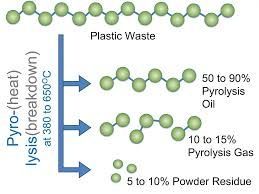

A biochar making machine is designed to convert biomass into biochar through pyrolysis (heating in a low-oxygen environment). To meet EBC requirements, several factors must be carefully controlled during production:

a. Feedstock Selection

- Only clean, sustainable biomass (wood chips, agricultural residues, forestry waste, etc.) can be used.

- No plastics, treated wood, or industrial waste are allowed.

- Moisture content should ideally be between 10–15% to ensure efficient pyrolysis.

b. Controlled Pyrolysis Conditions

- Temperature range: Typically 400–700°C, depending on the desired carbon stability.

- Residence time: Biomass must stay in the reactor long enough to ensure complete carbonization.

- Low oxygen environment: Prevents combustion, ensuring the production of stable carbon instead of ash.

Modern biochar making machines have automated control systems to regulate these conditions, ensuring consistent quality.

c. Emission Control

- Advanced machines are equipped with gas recycling and filtering systems.

- The syngas generated during pyrolysis can be used as fuel to power the process, reducing emissions and improving energy efficiency.

- Compliance with EBC standards requires minimal air pollutants during production.

d. Consistent Quality Output

- The resulting biochar is tested for carbon content, volatile matter, pH, and heavy metals.

- Only biochar with high carbon stability and low contaminants qualifies for EBC certification.

3. The Benefits of EBC-Certified Biochar

Using EBC-certified biochar offers multiple advantages:

- Agriculture: Improves soil fertility, increases water retention, and enhances crop yields.

- Carbon Sequestration: Locks carbon in the soil for hundreds of years, contributing to climate change mitigation.

- Environmental Safety: Guarantees that biochar is free of harmful substances, making it safe for long-term use.

- Market Trust: Certified biochar can be sold at higher value, giving producers a competitive edge.

4. Conclusion: Meeting Global Standards with Biochar Making Machines

Producing high-quality, EBC-certified biochar requires the right feedstock, controlled pyrolysis conditions, and advanced emission systems—all of which are achievable with a modern biochar making machine.

For businesses and farmers, investing in certified biochar not only supports sustainable agriculture but also contributes to the global fight against climate change. By following EBC standards, biochar producers can ensure their product is safe, effective, and environmentally responsible.