Tyre to Oil: Recycling a Worn-Out Resource for a Greener Future

Every year, over 1.5 billion vehicle tyres reach the end of their life globally. Their durable, complex structure—designed for safety and longevity—makes them a disposal nightmare. Stockpiles become fire hazards and breeding grounds for pests, while illegal dumping creates toxic scars on the landscape. For decades, the "solution" has been shredding for civil engineering fill or burning in cement kilns—downcycling methods with limited value and environmental concerns. But a transformative technology is gaining traction, turning these problematic black circles into a valuable "black gold": tyre pyrolysis.

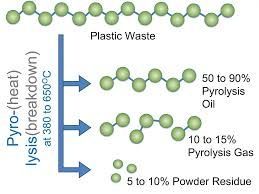

The process shares a name with its plastic counterpart but faces a unique set of challenges and opportunities. Tyre pyrolysis involves feeding shredded tyre chips—steel wires and all—into an oxygen-free reactor. Heated to extreme temperatures, the vulcanized rubber breaks down. The organic materials (natural and synthetic rubber) gasify and are condensed into oil, while the inorganic components are separated.

The output spectrum is particularly rich:

- Tyrene Oil: A high-calorific value, diesel-like oil that can be used directly in industrial burners or refined into transportation fuels. Its high diesel yield makes it particularly valuable.

- Recovered Carbon Black (rCB): This is where the story gets exciting. Unlike the char from plastic pyrolysis, the solid output from tyres is a fine, high-quality carbon black. Traditionally, carbon black is manufactured by burning heavy petroleum oils—an extremely carbon-intensive process. rCB offers a sustainable alternative, and its market is exploding as major tyre manufacturers like Michelin actively seek it out to reduce their carbon footprint.

- Scrap Steel: The steel belts and beads are cleanly recovered and sent directly to metal recyclers.

- Syngas: Again, used to power the process, enhancing efficiency.

The innovation in tyre pyrolysis is less about the core thermal process and more about the refinement and application of its outputs, particularly rCB. This isn't just recycling; it's upcycling. We are taking an end-of-life product and creating a high-demand industrial raw material, displacing a notoriously "dirty" manufacturing process. This creates a powerful double environmental benefit: diverting waste from landfills and avoiding the emissions from virgin carbon black production.

Furthermore, tyre pyrolysis is a champion of local, decentralized waste management. Instead of shipping massive volumes of bulky tyres over long distances to a few centralized processing facilities, smaller-scale modular tyre to oil plant can be deployed near major sources of tyre waste (e.g., large cities, mining operations). This drastically reduces the carbon emissions associated with transportation and creates local energy and material loops.

Of course, the industry must navigate challenges. Ensuring consistent quality of rCB is paramount for its acceptance by large manufacturers. Advanced post-processing techniques, like milling and pelletizing, are being developed to ensure rCB meets strict industry specifications.

Secondly, the syngas must be carefully managed and scrubbed to ensure any emissions are clean and within strict environmental standards.

The narrative around tyre pyrolysis is one of resource recovery in its purest form. It doesn't just eliminate a waste problem; it actively reverses it, mining the "urban mine" of discarded tyres for valuable commodities. It provides a tangible answer to a very visible global waste issue, transforming environmental liability into economic opportunity. As the technology matures and markets for rCB grow, the vision of a world where no tyre ends up in a landfill or a stockpile is moving from an idealistic dream to an achievable reality. The humble tyre is finally coming full circle.